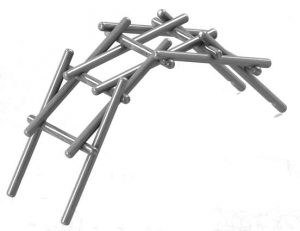

Geometric description and assembly of the framework

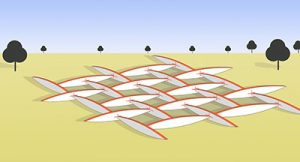

Identical beam members are loosely linked in a cross-hatch assembly arrangement on a flat surface.

In the application for architectural construction, this minimizes the need and cost of construction machinery.

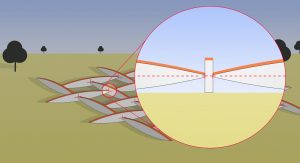

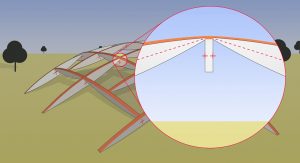

In a simple model, each truss member is supported at each end by a junction point mounted on (or integral with) the centre of a transverse beam.

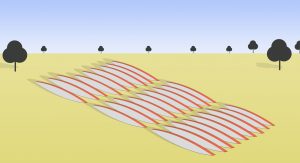

As more trusses are added, the flexible network of beams may extend from a central point outward, to any given size requirement. A structure is effectively woven.

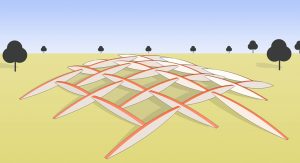

The junction units may be fitted with a small, pressurized lift unit, which is pre-programmed to lift on demand to a given degree. This provides a small, limited separating elevated displacement within the intersection at each supporting truss. Each small individual lift displacement is activated, and they accumulate, thus “raising” the structure as a whole before one’s eyes.

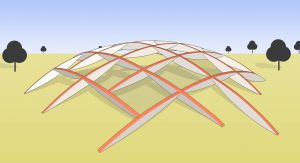

Each displacement may then be locked. Locking may be permanent or temporary.

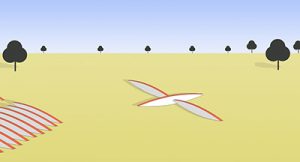

A continuous wave motion may be achieved for non-structural applications, in which case displacements would not be locked but instead be programmed to a continual flux movement.

All junction units may extend to pre-set limits of displacement, or extent of lift.

The junction point elevations may be controlled manually or automatically:

- Manual constructions may produce the elevation by means of pre-cut interlocking beam-ends or screw jacks.

- Automated constructions may be achieved with a pressurised lift unit.

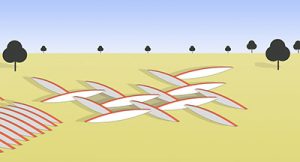

The whole assembly, from a flat framework to a self-elevated convex form as multiple truss rises accumulate, may occur at the press of a button. Hence, a shell-like structure is created, consisting of a series of parallel north/south segmented arches, interwoven with a series of parallel east/west segmented arches.

Once erected and locked, the structure is extremely stable, yet it retains local limited flexibility. This allows the complete structure to be raised further in a series of steps, by inserting column footings stepwise under each leg individually without undue stresses or the need for major weight lifting machinery. It also allows for uncomplicated extensions.

The self supporting nature of this structure has the ability to flex in response to loads applied in an upward direction, but to resist such flex when subject to loads in a downward direction, thus, footings, walls etc. can be established after the structure is erected. The flexibility also accommodates disaster zone terrain.

Components for a transportable, re-usable structure may be designed with form, application and structural engineering ratios in mind, as well as packaging, nesting storage and covering.

This system allows large areas to be covered quickly, conveniently and inexpensively.

Temporary structures can be demounted by first applying supporting pressure, then releasing each lock, manually or automatically, to allow the structure to gradually collapse at a controlled rate, back to its initial flat profile. The trusses may then be uniformly stacked, nested in bundles, transported and stored until required. Lightweight components, for example tent and marquee structures, can be erected and demounted manually without the need for the automated pressurised lift unit.