Bearing loads must also be individually assessed and certified with regards to size, building materials and purpose of structure. The forces required to raise structures of a particular size must also be individually calculated.

EXAMPLE: A self-erecting 300 m2 structure can be accomplished in 9.2 minutes:

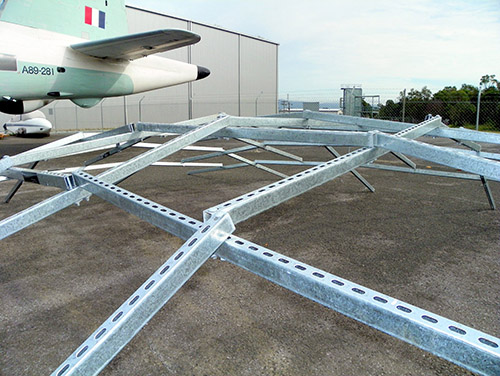

63 identical beams up to 250 kg each and 5.0 m. long.

Each beam incorporates a pressurised device (hydraulic cylinder and piston), which activates a separating movement of 166mm. at the centre of each beam.

A standard domestic water pressure washer unit, ie, a 1.5 Kilowatt pressure pump delivering 5 litres/minute at 15Mpa (150 bar) pressure, will fully erect this structure from a flat assembly to a locked convex form in 9.2 minutes.

Volume to extend each device is 0.73 Lit.

Pressure rated, 5mm nylon tubing is used to interconnect devices and pump.

Larger hydraulic cylinders and/or higher pressures will allow far heavier beams and extremely large structures to be assembled.

Quantities of identical, uniform beam members can be factory-produced.

Materials may range from ultra light, to prefabricated steel, to cast reinforced concrete, depending on the application.

Coverings can be membrane or semi rigid panels as required.